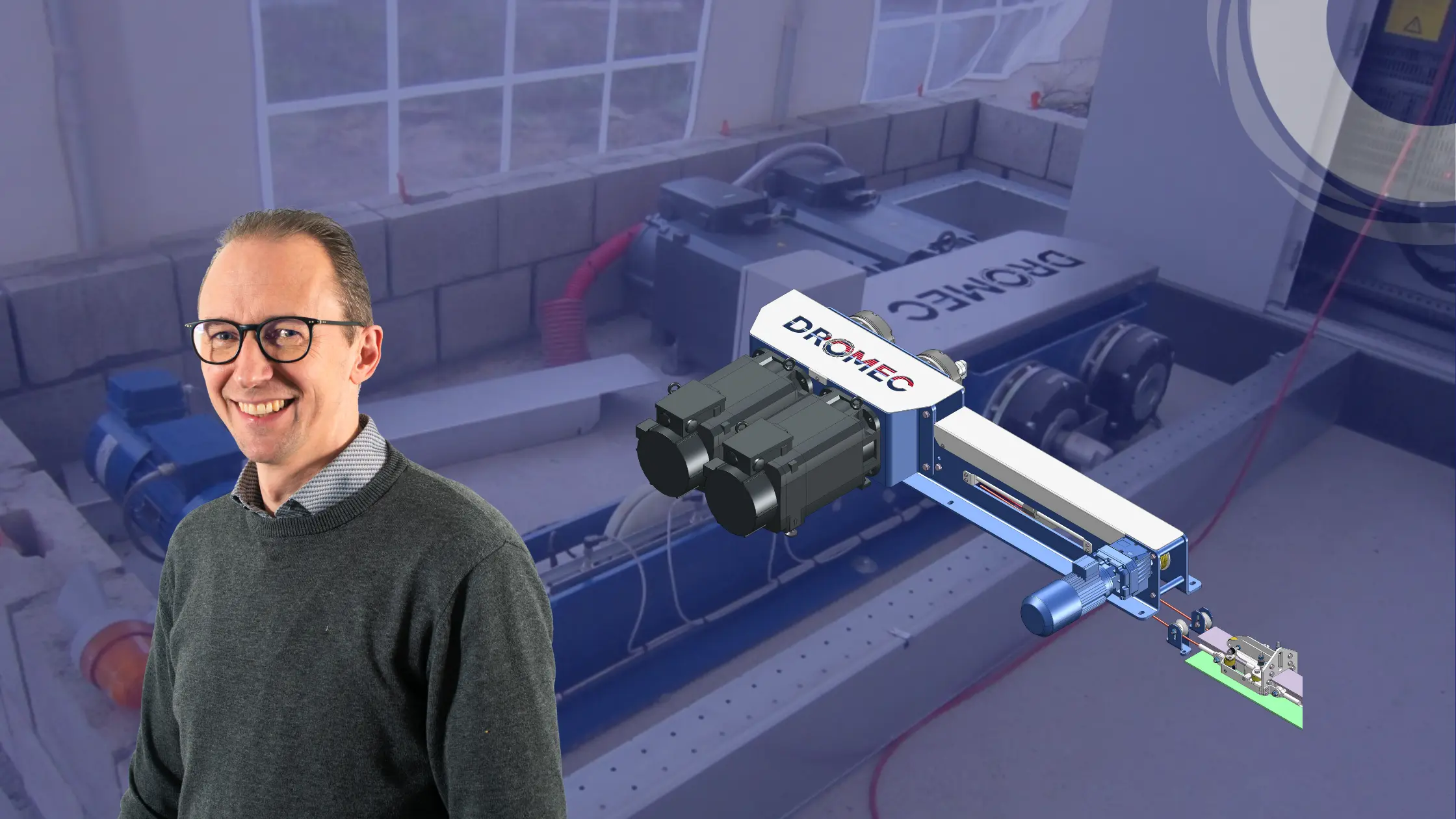

Geerart de Vree, CTO at DROMEC

a technical talent!

Geerart has been the technical brain at DROMEC for almost twentyfive years. From the very beginning of the development of winch systems, Geerart has been involved in projects. This also reflects his “database”: not only on the computer but also circulating in his mind. With a sparkle in his eyes, he explains: “We have grown, not only with our people but also in the complexity of our projects. That’s where I find the greatest challenge. You grow from being a draftsman to an engineer, and now I personally guide and coach our team of 8 engineers on every project. That gives even more satisfaction in your work, because together we reach a higher level of knowledge.”

Listening and analyzing

Geerart’s strength as a person within DROMEC lies in his sharp analytical ability. He is able to listen carefully to the customer’s needs. “How can we as engineers develop a winch system to lift or pull a load safely on site? You don’t see every project, but especially the complex, technical challenges. From the start at sales, I contribute to a high-quality solution that works simply. And then, as engineers, we are bound by Newton’s laws, even though sometimes we deal with people who think those laws don’t apply to them,” Geerart says with a wink.

Project supervision

“As soon as the engineer starts working on the project, I join in to brainstorm about the technical-mechanical aspects and the integration of the winch system’s control. Together we analyze what is technically possible and which components are needed. In our team, with the experience and knowledge I have built up, I try to ensure that the overall knowledge level functions at a high standard. Sometimes it is good to make connections between the wide variety of projects, and in doing so, we at DROMEC can truly draw on our history. Every project starts anew, sometimes with similar parts from earlier projects or situations. Then we assess what is economically feasible and look for the optimum solution for the customer. Once development is completed, it is built in the workshop and we start testing. As engineers, we also observe in the workshop to ensure the winch system works and functions according to the customer’s wishes.”

Highlight

“A project I would like to highlight is one from 2014. The customer, Maes from Belgium, made crash-friendly lampposts designed to prevent damage to cars and injuries to occupants. These lampposts could bend twice, and tests were needed to determine at what speed this would or would not occur. For this, DROMEC developed a winch system that pushed a car to a speed of 100 km/h over a distance of 100 meters. At a certain point, the winch released the car, and the effect could be measured. DROMEC built a test setup to simulate the situation to scale. The car was pushed forward by the winch. Safety was paramount—how precisely can you control this with a vehicle in combination with its environment? This was a safety-oriented project, and the customer was very satisfied with the development, in which he recognized his requirements and wishes in the design. Once again, it’s that technical challenge that excites me!”

Contact Dromec